Project Description

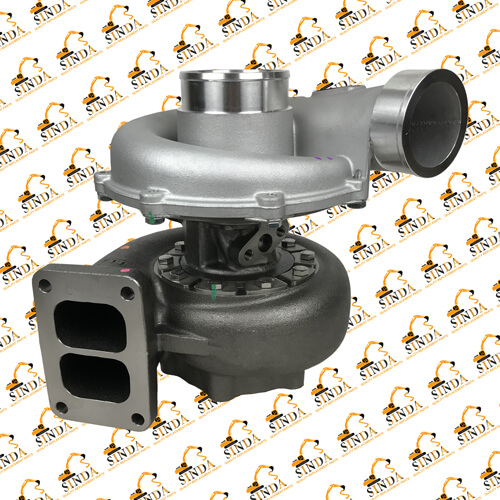

Turbocharger Information

| Description: | Turbocharger | Part NO.: | VA300019 VB300019 |

| Turbo Model: | RHC93 | VA300025 VB300025 | |

| Engine Model: | 6WG1TC | VC300025 VD300025 | |

| Cooled Type: | Oil Cooled | OEM NO.: | 1144003840 114400-3840 |

| Fuel Type: | Diesel | 1144003841 114400-3841 | |

| Place of Origin: | China | C92CND-S0025B C92CNDS0025B | |

| Package: | Neutral Packing | C92CND-S0025G C92CNDS0025G | |

| Warranty: | 6 Months | Application: | Hitachi Excavator ZAXIS600 with 6WG1TC Engine |

| HS Code: | 8414803090 | ||

| Brand Name: | SOMP / CUSTOMIZED | Hitachi Excavator ZAXIS800 with 6WG1TC Engine | |

| weight: | 22.25 KG |

Why should you choose our Sinda turbochargers?

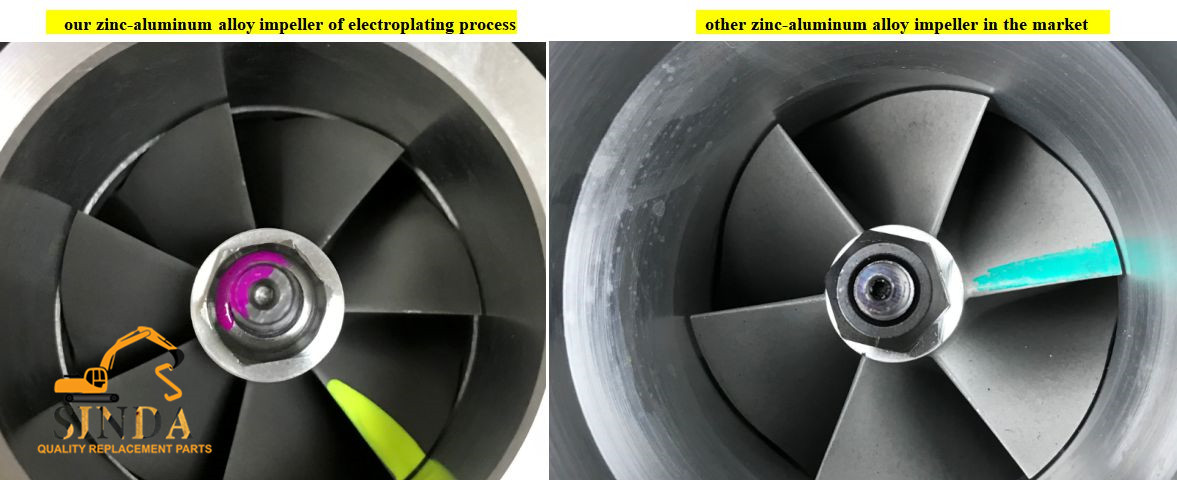

- C355 Zinc aluminum alloy with plating technology for compressor wheel

- K418 shaft & wheel, heat-resistance>950℃

- Turbine housing with Silicon and molybdenum, high temperature & wear resistance

- 100% Balancing testing for every turbo core

- Nice detail processing & finishingto make the whole turbo look more smooth

- Final inspection for turbocharger one by one to ensure the reliability and there will be “QC PASS” stamp on the compressor housing to prove the quality and performance

- OEM service is available

Packing & Shipping

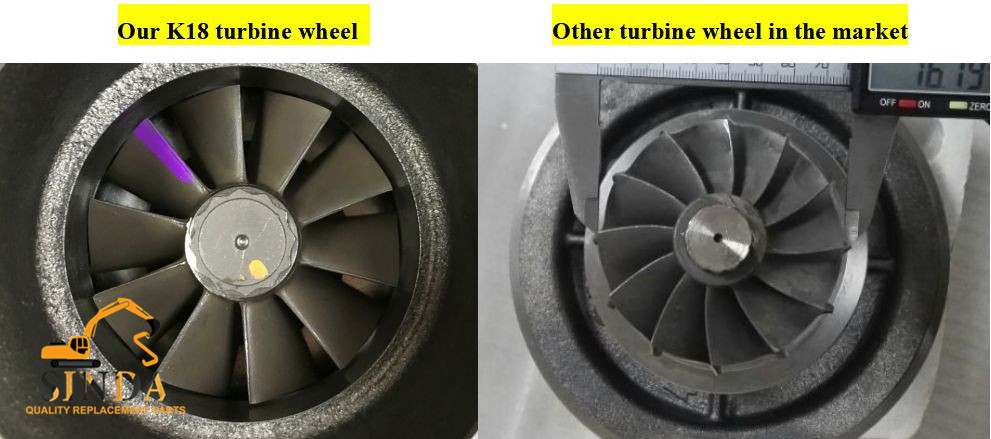

Quality Control for Turbo compressor & Turbine wheel

We always do our best to keep the price as low as possible without sacrificing the quality, and we are constantly invesitigating new methods of quality improvement. Each and every turbocharger manufactured is tested, inspected, and is guaranteed to meet the performance and specifications.What we are sure is that we could deliver qualify products continuously.

Here is the simple comparison for turbine wheel and compressor wheel between our turbocharger and the other turbocharger in the market.

Turbine wheel comparison:

Compressor wheel / impeller comparison:

Comparison for K13 and K18 material for shaft & wheel

| K13 turbine wheel | K18 turbine wheel | |

| Color | dim | Bright/Shining |

| Plating process | Uneven | Evenly distributed |

| Nickel content | 34%-38% | 75% |

| Melting point (℃) | 600℃-750℃ | 850℃-950℃ |

Also, even some suppliers told you their material is K18, but not all of them will use the best level of K18. There are many quality level even for the same type material. But there is one thing on common that you could simply tell the difference by eyes. The good material looks more bright and smooth, no graininess because the material and plating technology is evenly distributed on each blade.

We always pay close attention on the quality control and detail processing. Also, each turbo need to be inspected before sending from factory and there is “QC PASS” to approve the quality.